Automobile Military project Education Medical care Jewellery cultural relic protection |

Application area

1. Speed up production and shorten the time of R & D delivery

Compared with other development processes, it takes only a little time to move the idea from a design studio to a production workshop. With unprecedented speed and efficiency, prototyping, testing and production of various tools, fixtures, fixtures and available parts are made. Receive Auto Innovation Series, understand main 3D print breakthrough technology latest progress, help automobile manufacturers and suppliers to enhance competitiveness.

2. Fixtures, fixtures and Fixtures

For specific tasks, components, individuals or equipment, the free optimization of fixtures, fixtures and other manufacturing auxiliary appliances.

Custom engagement on complex surfaces

Minimize the loss of part processing

Optimizes access, but does not increase costs

Light quality, ergonomics

Select, place, move, keep, transfer, check, locate

3. Mold / assembly / alignment aids

Fast matching of complex geometries

From CAD to tools using GD& T reference

Dealing with complex geometries

Quality: softer than base material (not scraped), repeatability

Cost: set multiple parts together to save time from design to part installation.

4. Test and test

Functional model substitutes for parts

Decision making instrument

CMM inspection fixer

5. Customized small-scale production

Customize vehicles in a specific area or market, while keeping custom vehicles synchronized with the development of the remaining products. Use 3D print material to customize repair parts, repair parts and accessories. Receive Auto Innovation Series, understand main 3D print breakthrough technology latest progress, help automobile manufacturers and suppliers to enhance competitiveness.

Application case

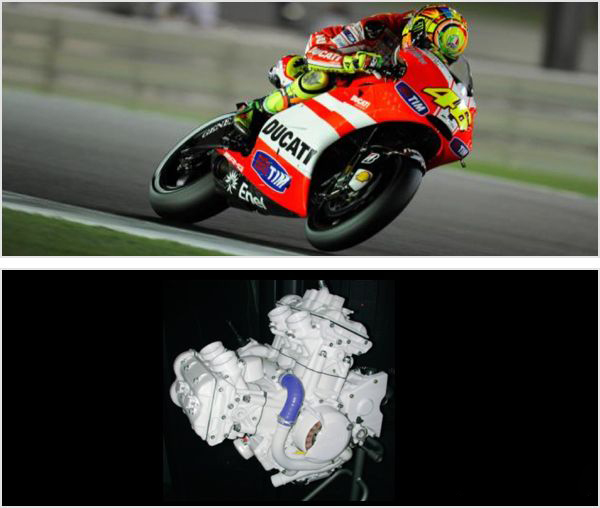

1. Ducati shortening market entry time

With the help of Stratasys technical prototyping, motorcycle manufacturer's acceleration engine design

Challenge

• The engine costs 28 a month's time for design and production

• Shortening the time to market for new products

• Eliminate outsourced delay

• Get a more reliable prototyping program

Result

• Reduce design errors

• Speed up the design process

• The time of listing is shortened by 29% (8 month)

• The cost of prototyping is greatly reduced

2. Carbon fiber wrapped 3D printing

Efficiency maximization of organic shape

Sparse filling to reduce 72% weight

Save 58% cost

The delivery time is shortened by 92%

3. Speed up the design of motorcycle engine

Challenge

• The engine costs 28 a month's time for design and production

• Shortening the time to market for new products

• Eliminate outsourced delay

• Get a more reliable prototyping program

Result

• Reduce design errors

• Speed up the design process

• Shortening of the time of the market 29%(8 个月)

• The cost of prototyping is greatly reduced

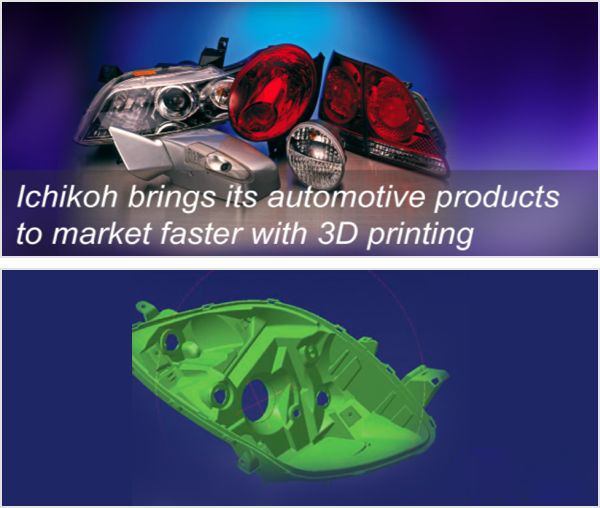

4.Speeding up the cycle of auto products

Challenge

• The time of delivery is long and the process is expensive

• Wide verification and design diversity

• Errors in the mold need to redo the process

• Fine multi material parts

Result

• Speed up the cycle of product listing

• Improving product reviews and redesigns

• Reducing the cost of prototyping

• Need to remove changes after forming

5.The design of Bentley using 3D printing technology

Challenge

• A model of diverse materials and exquisite details

• Reduction of large parts in proportion

• Evaluation of external and internal parts

• The project is expensive and long

Result

• Make the process fast and economical

• Bring better evaluation and test

• Improving the accuracy of the prototype

• Allow the production of multi material parts

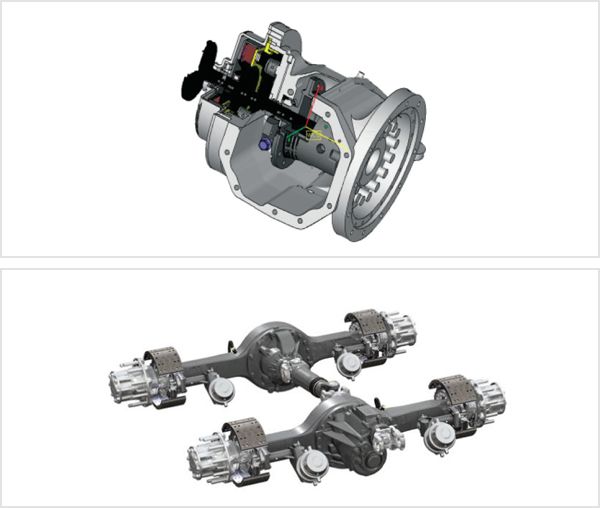

6.Dner company uses 3D printing to simplify the design

Challenge

• Long archetype Qie Anggui

• Design errors need to be identified in advance

• A complex device

• Limited capacity / traditional machining method

Result

• Allow early identification of design errors

• Save time and cost, thus reducing the cost

• Provide the beginning for the new design

• Provide rapid, economical and affordable prototypes

Application direction

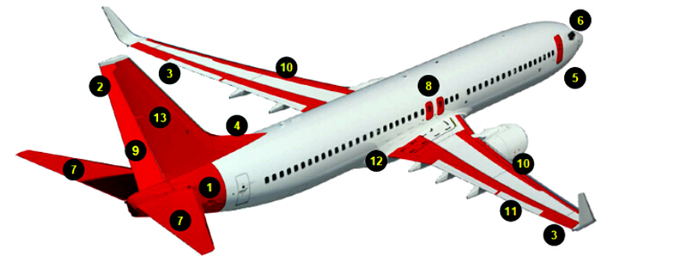

Aeronautics and Astronautics application

● Parts positive reverse design and structural optimization design verifying through 3D printing structure

● Surface detection check error by scanning comparison

● Assembly clearance assessment evaluation of assembly clearance ratio by scanner

● Using 3D printing technology to design production moulds, inspection tools and compare and analyze existing inspection tools

● Aircraft interior decoration printing

● Hair embryo structure printing

3D scanning technology can be used in the development and manufacture of the following parts in the field of aircraft manufacturing

01. Fuselage 02.Shield board 03.Cover plate

04.Dorsal fin 05.door 06.Cab

07.Horizontal diazepam 08.Interior structure of engine room 09.Rudder

10.Engine 11.wing 12.Landing gear

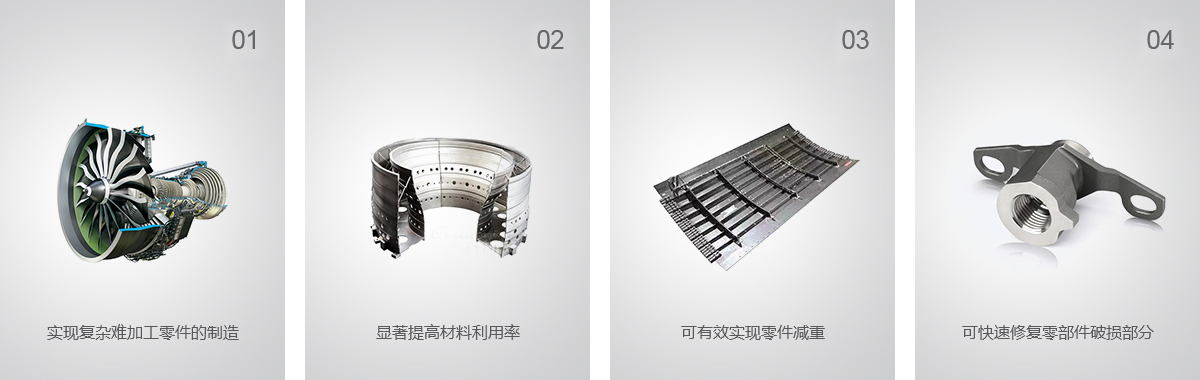

Application advantages of 3D printing technology in aerospace industry

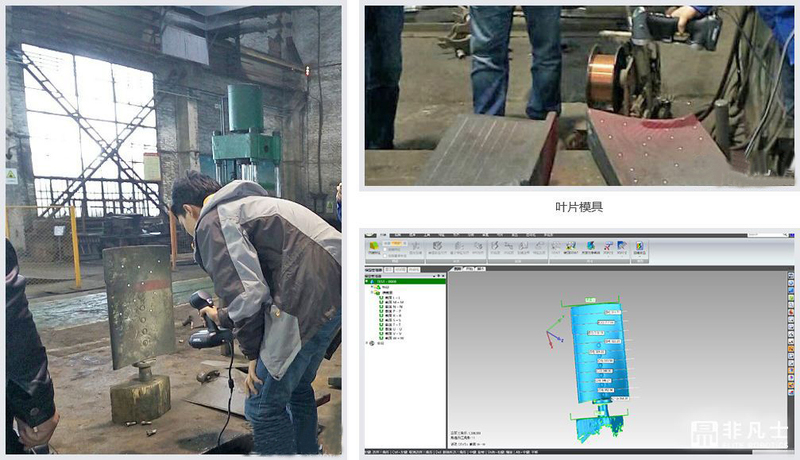

Application of blade scanning

● Digital modulus alignment

● Cross section comparison

● Assembly simulation

● Simulation of blade loading

Concept guidance

Rui Puchuang customer education solutions to STEAM education and creating educational philosophy as a guide, provide solutions to meet a wide range of learning resources and student-centered, problem oriented, demand mode to cultivate the ability of activities as the center is based on the requirements of.

Building a guest practice room

Different from the traditional to do confirmatory experimental subject teaching laboratory, creating Laboratory for cultivating students' scientific literacy, the development of students' creative potential, to stimulate innovation and willingness of students, the implementation of research study comprehensive practice platform for basic education is to create innovative education environment, promote the students' innovative spirit and practical ability, an important way to meet personalized learning needs.

Creating laboratory generally includes six functional areas: practical creation area, sharing work area, exhibition area, production area, processing area, intelligent multimedia tools supplies; ensure that there is a fixed time and places, there are full-time / part-time teachers, there are a series of courses and the integration of resources carrying a passenger to ensure the smooth development of education.

Rui Pu chuang guest education for different age groups, to provide innovative customer laboratory construction projects of different styles and configurations.

Primary school creation Laboratory

Junior high school students' Laboratory

The practice area is the hands-on creation area: the student completes the group discussion and the design work;

The discussion area is the exchange and sharing area: the student's own idea of sharing and discussing the exchange between groups;

Exhibition area: students show their own works and learn from each other.

Processing area: students process their work in the area;

Tool and equipment area: placing 3D printers, laser cutting machines and other large equipment, fixed area shared use

Training for teachers

Rip a teacher training plan perfect, strengthen cooperation, carry out various forms of training, such as "teacher training" off the record "Chinese youth hit off the Olympic training and other training activities, and carry out the weekend school teachers teach salon activities.

Curriculum construction

Curriculum system

It provides courses such as creating courses, 3D design, 3D printing, open source hardware, programming, robotics and other series courses and project production courses to meet normal school teaching. According to the characteristics of schools, it provides technical support to research and develop school-based courses.

3D printing and 3D design course

According to different age groups, we offer different 3D content printing courses. We also offer curriculum related courseware, lesson plans, curriculum packages, and create a communication community.

Open source hardware

The use of at least 27 kinds of sensors and other sensors of different interfaces provided by Arduino general controller, DFRobot and so on

(such as Shengsi module, KenBlock module, Microduino magnetically absorbing module)

Programming

In combination with open source hardware, a graphical programming system is used to start primary programming learning, and the students' logical thinking ability and programming ability are trained in a shallow and deep way. Through project practice, guide students to complete their programming works and show them.

Extracurricular activities

The rich extracurricular activities fully arouse the students' interest, establish a good environment for innovation and innovation, and let more students know the creation and experience innovation.

Event activity

In recent years, STEAM education and creative education have developed rapidly, and a number of teachers and students have achieved good results. In the national primary and secondary school computer production activities, aerospace competition, National Youth Science and technology innovation competition and other events, we see more and more students create good results. While lamenting the works of students, we also see some achievements of Chuang Ka education, which has been affirmed by the education department, so as to guide more teachers to participate in customer education, so that more students can accept the new educational mode of customer education.

Space characteristic scientific and technological activities

The establishment of space creating Education Alliance Program Chinese school construction center for international exchanges and cooperation in space science and technology to provide space for Rip characteristics of school curriculum and characteristics of aerospace, aerospace science and technology to the development and integration of educational resources, and promote the exploration of production services for small and medium-sized education reform mode and way of integration, the cooperation quality of scientific quality education.

Experts and scholars are invited to go to school to carry out space knowledge science activities for students, carry out experience activities such as NASA summer camp, small space journalists, aerospace technicians, small astronauts, etc., through various ways, let students get close to space and experience space, and eventually become an aerospace small pioneer.

Orthodontic correction

Invisalign

With the help of 3D 3D printing and scanning technology, a kind of polymer resin material molded laminated braces, patients every two weeks to replace a pair of teeth, reach the effect of moving gradually. A traditional metal bracket that can completely replace about 30% patients.

The thickness is only 0.5mm Stealth comfortable removable band

Complementary medicine

Preoperation model

For orthopaedic department of orthopedics surgery, preoperative surgical plan can be made by 3D printing and shaping the local bone model of patients. According to the solid model, a more precise and complete surgical plan is developed to improve the therapeutic effect. The preoperative physical model of the complex Department of orthopedics will also improve the speed of the operation and the success rate of the operation.

Case 1

Case 2

Case 3

Surgical guide plate

The surgical guide plate is a computer-aided design and manufacture tool for auxiliary operation. It can ensure the correct location and direction of operation in implantation, cutting and drilling. Because each of the surgical guides is unique, 3D printing is the most economical, fast and effective solution.

Application of surgical guide plate

As this type of printing needs to be exposed to the human body, there is a medical certification requirement for the material, and the technical personnel of the relevant medical background are required to deal with the data. Although we haven't done any surgical guidance class technology service yet, as long as people with relevant medical background and a little 3D printing technology training, we can carry out this kind of work. Our existing Fortus and Objet devices have multiple different medical certification printing materials, as follows:

Equipment | Material Science | Explain |

| Objet | MED610 | The material is suitable for the use of long-term skin contact (30 above) and short-term mucous contact (the longest 24 hours). Biocompatible materials have been approved by 5 item medical approval, including: cytotoxicity, genotoxicity, delayed hypersensitivity, allergy and USP plastics VI level. It is very suitable for the guide plate of implant surgery |

| VeroGlaze (MED620) | It provides the best color match in the industry. VeroGlaze is an ideal material for making denture pastes and wearing diagnostic wax. It is approved in medicine and can be placed in the oral cavity for , 24 hours. | |

| Fortus | ABSM30i | Build functional prototypes, tools, and can pass through gamma or ETO the end use parts for germicidal. This engineering thermoplastic has good mechanical strength and is in line with ISO 10993 and American Pharmacopoeia plastic VI grade standards. |

PC-IS | It is a biocompatible material with the highest strength and the best heat resistance in the FDM technology. It passes through gamma, ETO sterilizing and conforming to ISO 10993 and American Pharmacopoeia VI grade standards. | |

| Ultem1010 | The certification level of this material is biocompatible, and has passed , NSF 51 and ISO10993/USP six level certification, which can be contacted with food. The material can be 3D a medical tool, such as a surgical guide that can be sterilized by high pressure steam. |

Orthodontic rehabilitation

For patients with scoliosis who need correction, similar to orthodontic treatment, a series of external orthodontic instruments designed in sequence should be used for correction in a long term, which involves medical treatment, 3D scanning and 3D printing technology. For a large number of fracture patients, the 3D printing apparatus also has a good application effect in the process of rehabilitation treatment.

Application of orthopedic rehabilitation

The application also has medical certification requirements for the material, and the technical personnel of the relevant medical background are required to deal with the data. It is the extension of the preoperation model, and there is a lot of space for the rehabilitation of scoliosis and upper limb fracture.

3D printing is being widely used in the area of jewelry customization because of its rapid prototyping technology. As the 3D printing technology is increasing, it has also made the jewelry custom made in the past maintain high cold posture, more ground to the ground.

3D printing process used in addition molding, compared to the traditional jewelry processing of the subtraction of more material can greatly reduce the production process.

Cost consumption. And the production of the model of high precision, early wax artificial cost, the later manual labor costs, can be saved. And profit

The jewelry materials can be calculated in advance by the modeling software, and the cost accounting can be estimated accurately.

3D printing technology can greatly improve the manufacturing speed of jewelry. For example, by making the wax pattern, highly skilled master, carving a ring of wax will cost three or four, slightly careless, had to start from scratch. 3D printing technology can make up to ten investment in two hours, to improve the efficiency of nearly 20 times.

The whole process of 3D printing is: computer modeling - 3D printer output. As long as the precision is allowed, whatever complex entity can be printed out. Compared with the limitations of traditional manual plate making, designers can freely give full play to their own ideas and design more creative jewelry.

3D printing the advantages of jewelry

Compared to the traditional jewelry production process, the advantage of 3D printing jewelry is that:

1. More quickly: traditional manual custom jewelry, we must have experienced craftsmen manual mold grinding, time-consuming, 3D printing jewelry accuracy is higher and less time consuming.

2. Cheaper: traditional handmade jewelry is expensive, 3D printers jewelry can be produced, reducing production costs and prices.

3. More freedom: compared with the traditional manufacturing industry, the complex structure of 3D printing technology can not be done by hand only need to set a good program, to re complex shapes can be printed out by the computer set so 3D printing technology makes up the artificial "yingshang".

4. More unique: 3D printing is more advantageous in jewelry design, and is more able to meet the customer's personalized needs.

The direction of cultural relics and Archaeology

Salvage excavation:It is the situation that the cultural relics are to be excavated as soon as possible when the cultural relics are facing difficult to preserve.

Research archaeology:Far from the urgency of the rescue excavation, the demand for time is relatively loose and more academic.

Salvage mining Research Archaeology

Salvage mining Research Archaeology

3D printing in archaeological advantages

The actual record of archaeological excavations can be recorded and the original features of the archaeological excavations are reproduced.

The current situation of the real record of the archaeological site, to provide the most comprehensive information on the day after

文保

More than 5000 professional and technical personnel who undertake the repair work of cultural relics in the country have to repair 1 pieces of cultural relics per person per month, only to repair the existing damaged cultural relics in the country at least for thousands of years.

Swallow motor bronze Three-dimensional scanning diagram

Swallow motor bronze Three-dimensional scanning diagram

Winchance

Five features of Virtual Museum

1.Unbounded: breaking the shackles of time and space;

2.Vividness: integration, optimization, superposition and exchange of information;

3.Influence: the real realization of educational science and technology without borders;

4.Autonomy: come and go without obstacle;

5.Communication: establishment of forum, message board, public mailbox

|

|